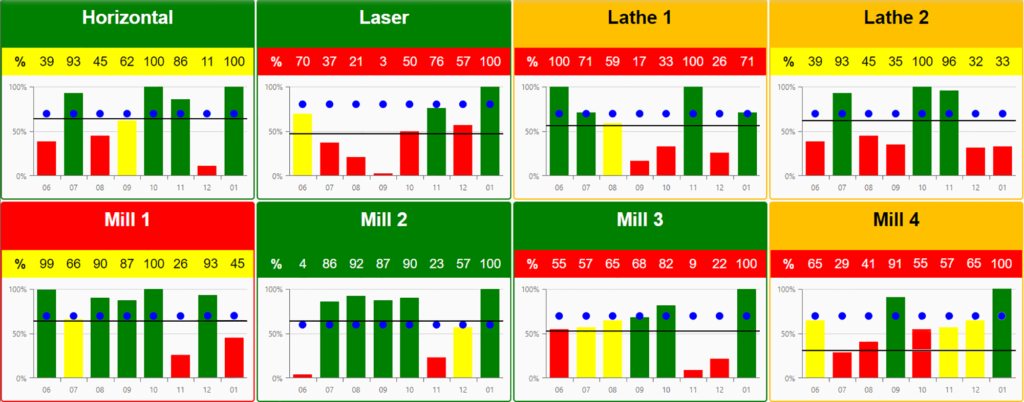

WHAT IS SCYTEC DATAXCHANGE?

Scytec DataXchange is a Cloud and On-Premise OEE and analytic manufacturing machine monitoring system, and so much more. In order to develop a machine monitoring system that truly meets the needs of 21st-century manufacturing, Scytec leveraged our 15 years of experience developing data collection, machine monitoring, and OEE software solutions. Through the use of innovative IIoT technology, DataXchange increases overall equipment effectiveness, utilization, and shop floor productivity.

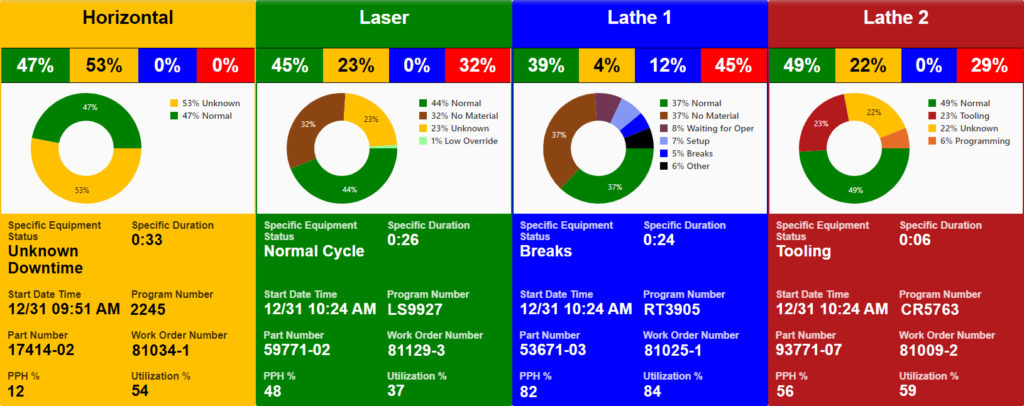

REAL-TIME EQUIPMENT STATUS

Scytec DataXchange provides a user configurable real-time manufacturing dashboard providing feedback as the data is collected in a user configurable interface. Scytec understands that lean manufacturers need up to the minute shop floor data, and equipped DataXchange with customizable manufacturing dashboards to provide feedback in real-time as utilization, downtime, and OEE data is collected.