ACHIEVE HIGH-ACCURACY DIGITAL TWINS WITH VERICUT USING A LIVE CONNECTION TO CNC MACHINES THROUGH SCYTEC DATAXCHANGE

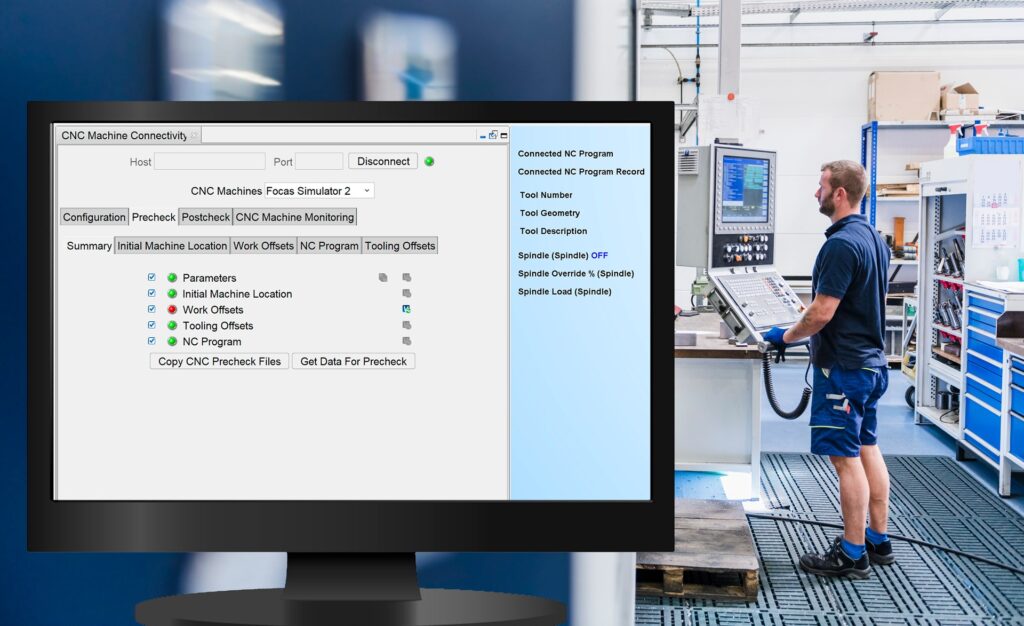

Scytec has partnered with Vericut, integrating the Scytec DataXchange shop floor machine monitoring system into Vericut via the CNC Machine Connect module. This integration gives users the ability to connect Vericut directly to CNC machines through DataXchange to utilize real-time data from the shop floor. Take your CNC simulation to the next level by creating the most accurate digital twin of your machines possible and establishing a more streamlined manufacturing process. Vericut CNC Machine Connect has three components, Precheck, CNC Machine Monitoring-Live Streaming and Postcheck.

VERICUT CNC MACHINE CONNECTIVITY HIGHLIGHTS

- Read machine setup information such as main NC programs, subprograms, axis locations, work offsets, and tooling to compare with Vericut’s Machine Configuration (VMC).

- Read machine parameters to improve Vericut’s digital twin machine.

- Identify differences between machine variables, parameters, and settings and update the Vericut simulation to verify that these values produce the intended result.

- Investigate potential issues that may have caused parts to be out of specification.

- Review any modifications to the NC program, subroutines, feed rates, spindle speeds, and more.

- Identify and review any errors or problems that resulted in overrides or emergency stops.

- Compare live cycle times to Vericut’s predicted run times.

PRECHECK

Vericut CNC Machine Connect allows users to conduct a Precheck after running a Vericut simulation and before manufacturing a part on the machine for the first time. Precheck verifies that the data and parameters used in the simulation match what is on the machine. This prevents unexpected errors from appearing when you run your part for the first time on your shop floor.

If Precheck shows that machine parameters and setup details such as the main NC program, subprogram, tools, length offsets, and more match what was in Vericut, it’s time to press Cycle Start on the machine. If differences are identified, users can investigate and update these on the CNC machine or use the Update feature in Vericut CNC Machine Connect to update Vericut with the machine data to rerun the simulation and ensure there are no new problems or unexpected errors before pressing the Cycle Start button on the CNC machine.

The Precheck component within Vericut runs when the simulation and verification is completed successfully. The Precheck results can then be viewed live, or the information can be saved for later use by the Precheck standalone application when the CNC machine is ready to start the job.

PRECHECK APPLICATION

This standalone application runs on PCs or Windows tablets out by your CNC machines and allows machinists to ensure that key aspects of the machine setup match what was verified in Vericut, without checking out a Vericut license. Differences identified can then be investigated and resolved before running the machine and risking problems resulting from those differences.

- Check that parameters from your physical machine and Vericut’s virtual machine match.

- Verify that job setup information on the machine (NC programs, subprograms, work offsets, etc.) match with the corresponding Vericut setups.

- Verify cutting tools and their length offsets match with Vericut.

- Verify work offsets on the CNC machine match with Vericut.

CNC MACHINE MONITORING-LIVE STREAMING FEATURE

Establish a live connection to CNC Machines on the Shop Floor. Vericut CNC Machine Monitoring allows you to live stream and monitor what your machines on the shop floor are doing in real-time, within Vericut. When you are not able to observe your CNC machine by standing next to it, find answers to questions like the following with the click of a button.

- Is my machine running?

- Which part and NC program or subroutine is currently running?

- What cutting tool is currently loaded and what active work offset is loaded?

- Is the machine running at 100% or has an override been adjusted?

- If my machine is stopped, why (emergency stop)?

Vericut CNC Machine Monitoring enables users to observe how the machine is functioning live as it is happening on the shop floor. CNC Machine Monitoring continually updates the connected Vericut session with the CNC machine’s axis positions, cutting tool in use, active tool and work offsets, and a wealth of information about how the machine is behaving and performing.

Use CNC Machine Monitoring to view past the machine enclosure, guards, flying chips, and splashing coolant to see where the tool is cutting on the part.

Monitored information can be viewed via Vericut’s Status window or HUD (Head Up Display), and includes the following:

- NC Program

- NC Program Record Number >>> Current block number

- Active Alarm

- E-Stop State

- Cycle Status

- Running State

- Controller Mode (I.e. MDI, Edit, Jog, etc.)

- Feedrate Override %

- Rapid Override %

- Spindle Override %

- Spindle Load

- Tool Offset

- Work Offset

Summary of the Features

- Observe what machines in the shop are doing

- See which NC program or subroutine is running

- Observe active tool and work offsets

- Monitor machine axis positions/motion and spindle activity

- See if spindle or feedrate overrides are applied

- See if a machine is (or isn’t) running or in an Emergency stop

- Recognizable colors provide enhanced visibility for monitoring:

Green – Machine is running, Spindle/Feedrate/Rapid set to use 100% of programmed values

Yellow – Spindle/Feedrate/Rapid override % reduced below programmed value ( < 100%)

Orange – Spindle/Feedrate/Rapid override % increased above programmed value ( > 100%)

Red – Machine not running due to Emergency stop, current machine state and/or cycle status

POSTCHECK

The Postcheck capability is an investigative tool which allows you to review archived data directly from the NC machine, within a Vericut simulation in order to observe how well the machine ran, as well as inspect and diagnose any issues that occurred during machining of a specific part.

SEE A DEMO OF VERICUT CNC MACHINE CONNECT

If you would like to see a demonstration of how real time data can improve your digital twins, click the image below to register for a demonstration of Vericut CNC Machine Connect.