MONITOR ALL OF YOUR EQUIPMENT

Why should your shop floor’s legacy equipment be left out of the benefits of modern manufacturing’s IIoT and Digital Transformation? The Scytec DataXchange machine monitoring platform was designed with both modern and legacy shop floor equipment in mind to enjoy all of the benefits of Smart Manufacturing technologies. With the Scytec Status Relay Controller (SRC), manufacturers can connect Scytec DataXchange to legacy equipment and pull data allowing for transparency and insight across all types of equipment on a shop floor. This guarantees that machines can run with minimal downtime, increased utilization and optimized part count tracking, and more. No programming is required, and the SRC is low-cost, expandable, has both digital and analog inputs and can connect to machines over wired or wireless Ethernet.

STATUS RELAY CONTROLLER

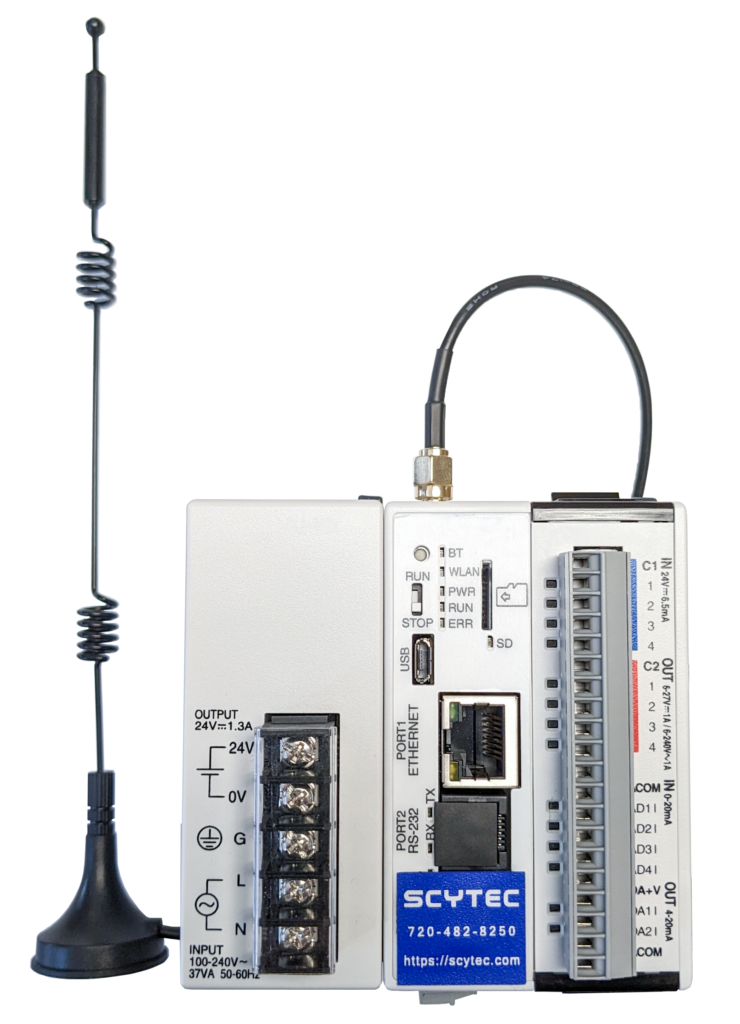

The Status Relay Controller (SRC) is a low-cost hardware device that comes programmed and ready to work with Scytec DataXchange for monitoring your legacy shop floor equipment. The SRC can be connected to a wired or wireless Ethernet network and is capable of monitoring digital and analog signals with built-in functionality around shop floor equipment. The SRC is available in two configurations, the SRC Standard and the SRC Extended.

CONNECTING EQUIPMENT TO THE SRC

Outputs from equipment or sensors are wired to the digital or analog inputs of the SRC. One or multiple inputs can be used to determine the status of the equipment or to collect sensor data. The Scytec DataXchange software can be configured to use any combination of inputs from the SRC.

SRC STANDARD

The Standard SRC has four digital inputs that can be configured in a variety of ways, all without any programming, providing a flexible, scalable solution. Each input can be configured to detect high or low signals, alternating signals, latch based on a pulse, or function as a counter.

The Standard SRC works great for monitoring stack lights to detect green, yellow, red, and flashing conditions, as well as other digital signals from the equipment. In addition, sensors such as proximity switches and current transducers are a great solution to determine cycle status and part counts.

• 2 Analog 0 – 20 mA

• 2 Analog 4 – 20 mA

• 4 Digital Inputs 24 Volts

• Detects State, Alternating, and Latching

• Configurable for State or Counters

• 4 Digital Relay Outputs

SRC EXTENDED

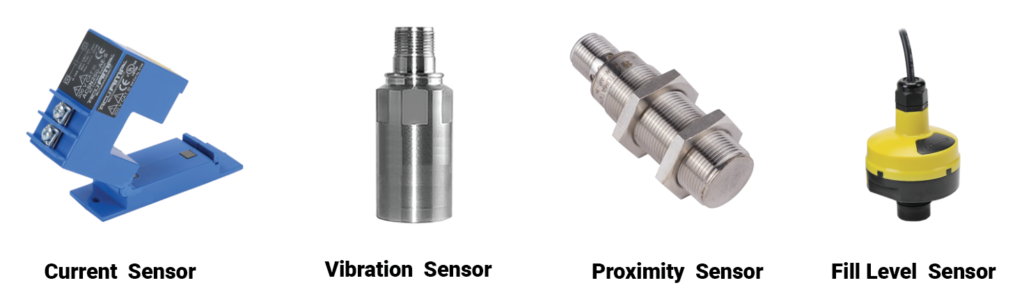

The Extended SRC has all the functionality of the Standard SRC with the addition of four analog inputs and eight additional digital inputs. The analog module can be one with 0 – 20 mA inputs or a module with 0 – 10 volt inputs. With either module, the scaling is configured and performed in Scytec DataXchange eliminating the need for any programming of the hardware. A variety of sensors such as current, vibration, temperature and fill level sensors can be used with the Extended SRC providing machine health monitoring in addition to tracking machine utilization.

• Add on Modules to the SRC Standard

• Choice of Analog Module

• 4 Analog Inputs 0mA – 20mA

• 4 Analog Inputs 0v – 10v

• 8 Additional Digital Inputs

• Additional modules can be added