COLLABORATIVE AND INDUSTRIAL ROBOT MONITORING

Scytec DataXchange can connect directly to both collaborative and industrial robots, allowing manufacturing facilities to have full visibility into unattended operations at all times. One of the many benefits of having connectivity to the robots is providing smart factory dashboards and real-time notifications to ensure operations continue to run smoothly. Connections to the robots can be over wired or wireless Ethernet without the need for additional expensive hardware solutions. With the full power of DataXchange, robots can be integrated into the same monitoring solution that can be used for all of your shop floor equipment, from CNC machines, fabrication equipment, and assembly, as well as legacy and manual machines.

MONITOR THE FULL CELL

Monitoring can take place from different devices within a manufacturing cell to provide an unprecedented level of detail into the state of the operation. DataXchange can pull data from the primary operation such as a CNC machine or welder, directly from the robot, and/or from presence sensors on material holders. Pulling data from all the devices within the cell allows for the identification of exact downtime reasons such as if the robot is waiting for the machine, if the machine is waiting for the robot, if the robot is waiting for material, or if one of the devices has an alarm or fault. Having data at this level provides the information needed to identify hidden issues and optimize the process to ensure production runs as smoothly as possible. Scytec DataXchange provides the smart factory technology to evolve your shop floor and take your manufacturing facility to the next level, which is a requirement in today’s

competitive market.

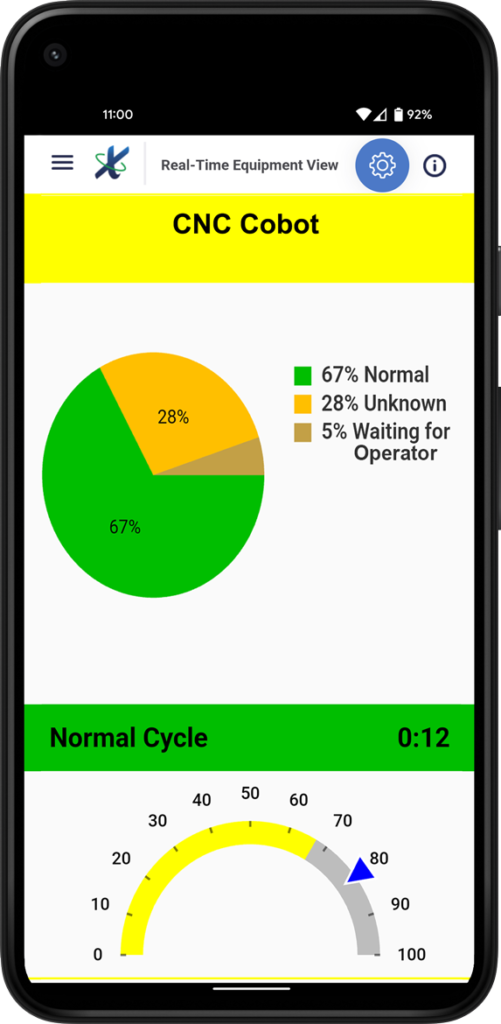

MONITOR ROBOT MATERIAL LEVELS

Unattended automated machine tending is great in today’s competitive manufacturing space until the raw material runs out and no one notices. Reactive actions to keep automated cells running minimize the value of these investments. Using Scytec DataXchange to monitor your robots, real-time information can be displayed on mobile devices and dashboards throughout the facility showing the level of raw material remaining. Based on part cycle times and the amount of raw material remaining, dashboards can show the amount of time before material will be depleted, allowing shop floor personnel to manage their time efficiently. In addition, Microsoft Teams, text messages, and email notifications can be sent when a material is low, providing critical feedback to ensure shop floor operations continue to run rather than sitting idle.

ALERTS FOR ROBOT DOWNTIME

Receive real-time notifications on dashboards as well as through Microsoft Teams, text messages, and email when an alarm or fault occurs on the robot. In addition to alarms, track when the robot has been paused, or how much time a cobot spends in teach mode. Understanding the details of how people are interacting with cobots allows for optimization of the processes. Customizable notifications and configurable dashboards along with historical data are the information needed to take the shop floor to the next level and ensure competitiveness in the connected manufacturing age.

ROBOT CONNECTIVITY

Common Ethernet protocols such as Modbus TCP, OPC UA, or MTConnect can be used to monitor most industrial robots and cobots without the need to use any hardware. Hardware is available for older equipment as well making Scytec DataXchange the perfect solution for all shop floor equipment regardless of the type, model, or age.