AFFORDABLE MACHINE MONITORING THAT RETRIEVES THE DATA YOU NEED FROM ALL YOUR SHOP FLOOR EQUIPMENT

Scytec DataXchange can collect OEE metric data such as utilization, part counts, downtimes and much more automatically over a wired or wireless Ethernet connection from standard protocols such as MTConnect, OPC UA, Modbus TCP, and directly using proprietary protocols from controls like FANUC, Haas, Heidenhain, Mazak, OKUMA, Siemens and more. The Scytec DataXchange machine monitoring platform has the ability to retrieve information off your shop floor equipment that goes far beyond running or not running, enabling manufacturers to solve their problems.

OEE MONITORING FOR LEGACY CNCs, MANUAL MACHINES, PLCs, WELDERS, COLLABORATIVE ROBOTS AND MORE

Scytec DataXchange machine monitoring can also collect automatically from older, manual machines and machine sensors using the Scytec DataXchange SRC, our low-cost PLC-based module. The DataXchange SRC ships preprogrammed and ready to work with your machinery directly from Scytec HQ.

DataXchange can monitor voltage signals, current flow, as well as triggering off devices such as light sensors for the collection of OEE metrics. Other common sensor types DataXchange can monitor include humidity, proximity, temperature, vibration, and more.

Fabrication equipment is also able to be monitored and opens your machine monitoring possibilities up to burn tables, laser cutters, saws, punch presses, welders, and more.

MACHINE MONITORING THAT IS AFFORDABLE, FLEXIBLE, AND SCALABLE

With Scytec DataXchange machine monitoring, providing unlimited reporting, charting, and dashboard usage, the pricing couldn’t be any simpler. DataXchange is licensed based on the amount of equipment that you want to monitor, with no required minimums.

Scytec DataXchange offers multiple licensing levels, allowing you to tailor data collection based on your equipment and smart manufacturing goals. Whether you’re just beginning with basic machine status tracking or need comprehensive performance analytics, the DataXchange machine monitoring system adapts to your needs. Licenses are fully transferable between machines and even across facilities, making it easy to scale as your monitoring requirements evolve. This flexible approach makes DataXchange ideal for small shops as well as large, multi-plant enterprises.

The DataXchange pricing and implementation are designed to scale from a few machines to multiple plants across time zones, enabling you to view and analyze machine data from anywhere at any time. The distributed design allows the comparison of metrics such as utilization, downtimes, and OEE reports & charts across machines and across plants. DataXchange is designed for shops with a few machines, as well as scaling to meet the needs of multinational manufacturing operations by harnessing the power of the Scytec Commercial Cloud, or with On-Premise installations.

UNLIMITED CHARTS, DASHBOARDS, LOCATIONS, AND USERS

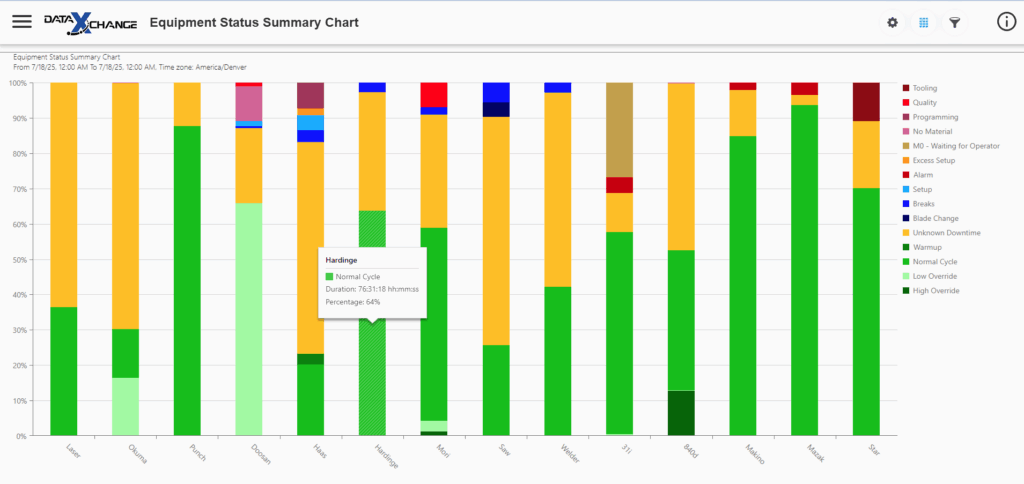

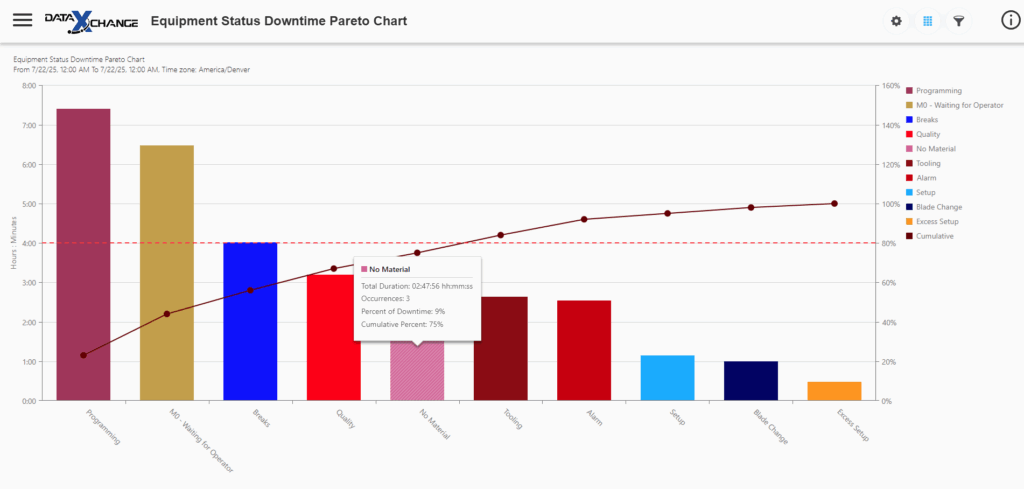

DataXchange offers unlimited use of the reports, charts and manufacturing dashboards in DataXchange to provide you with the information you need to monitor OEE and reduce machine downtime and increase shop floor productivity. The available reports and charts include…

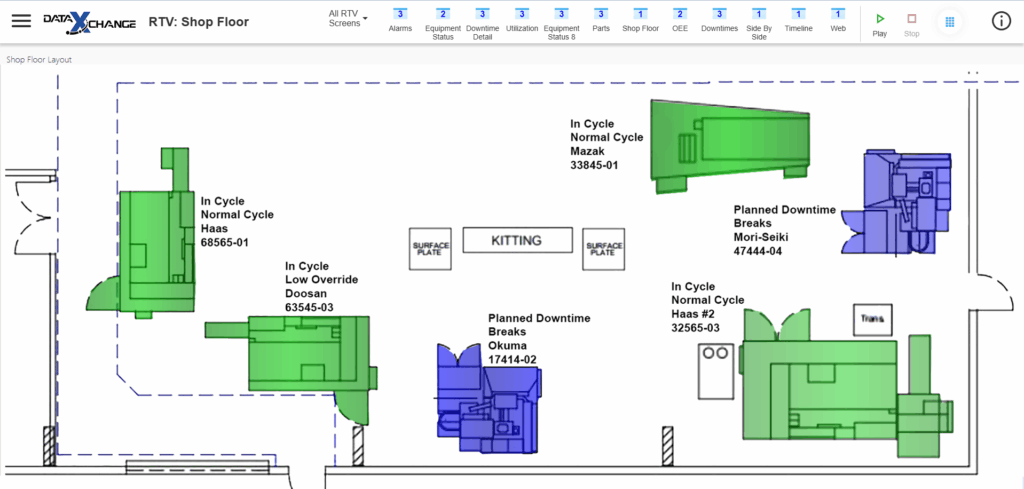

Machine utilization trends, equipment status summaries, OEE summaries, downtime and scrap Paretos and much more. The configurable Real Time Viewer (RTV) dashboards are unlimited as well.

There is no limit to the number of users who can use DataXchange. Additionally, an unlimited number of user groups can be created, providing easy management and providing users with information specific to their needs.

DATA COLLECTION THAT SOLVES YOUR SPECIFIC PROBLEMS

It’s one thing to collect data; it’s another to categorize the data based on your definition of what the machines are doing.

For example, is the machine in cycle during automatic tool changes, program and optional stops, or feed hold? How about when it’s running, but with the feed rate override at 80%, or during warmup cycles? The power of DataXchange allows you to make these types of decisions to meet your specific OEE monitoring needs, trigger notifications, increase shop floor utilization, decrease downtime, along with so much more.

APPLICATIONS THAT EVOLVE YOUR SHOP FLOOR

Scytec DataXchange provides iOS and Android users with the ability to see the current status of their equipment, as well as the ability to run their charts on phones and tablets with the mobile and browser-based reporting tool, Data Display.

Scytec DataXchange provides a centralized hub where you can access the mobile Data Display application and other DataXchange applications.

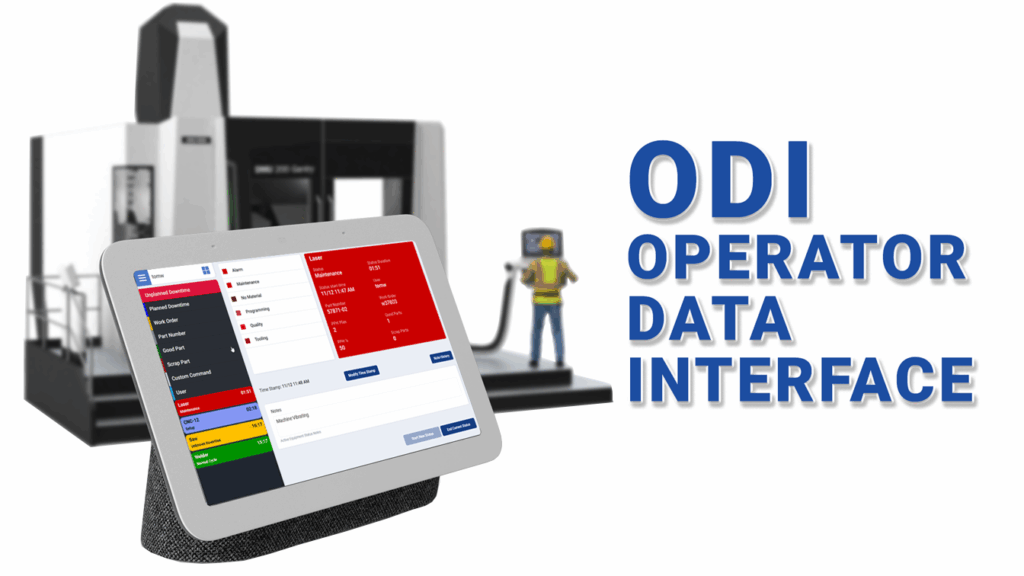

ACCURATE FEEDBACK FROM YOUR OPERATORS

While some of this information can be collected automatically or inferred from the data, many times input from an operator is needed. The DataXchange Operator Data Interface (ODI) is a supplemental application that provides an easy-to-use interface that runs on PCs and tablets to categorize planned and unplanned downtimes, part count tracking, as well as triggering and sending email and text notifications to keep everyone updated on the status of the machines. The Operator Data Interface is the perfect tool for your staff who operate more than one machine inside a cell.

INDUSTRY LEADING MACHINE MONITORING INTEGRATIONS

Scytec developed DataXchange utilizing cutting-edge web technology that enables DataXchange to integrate with manufacturing software such as ERP systems, scheduling systems and machine maintenance systems such as CMMS. Additionally, external files can be read automatically, along with the ability to integrate with external systems opening the doors to many third-party integrations.

VERICUT CNC MACHINE CONNECT

Scytec has teamed up with Vericut to integrate the DataXchange machine monitoring platform directly into Vericut through the CNC Machine Connect module. This powerful integration enables users to stream real-time data from their CNC machines into Vericut, enhancing simulation accuracy and supporting the creation of true digital twins. The result is a more streamlined and efficient manufacturing process. Vericut CNC Machine Connect includes three components: Precheck, CNC Machine Monitoring – Live Streaming, and Postcheck.

Contact our sales team to schedule a free demo and learn more about the features available in DataXchange OEE monitoring software that can increase productivity on your shop floor.