Leveraging Industry 4.0 Technology to Enhance CNC Machine Digital Twin Software: A Closer Look at CNC Machine Connect from Scytec and CGTech

In today’s fast-paced manufacturing landscape, the integration of cutting-edge technologies has become imperative for businesses seeking to optimize their operations and gain a competitive edge. One such technology that has revolutionized the manufacturing industry has been machine monitoring platforms like Scytec DataXchange. DataXchange offers shop floor insight and assurance for manufacturers by accessing real-time data pulled off shop floor equipment for dashboards, analytics, and historical reporting. Digital Twin software, such as CGTech VERICUT also offers manufacturers assurance by ensuring that products are produced by machines correctly, and the integrity of shop floor equipment is maintained with no errors or collisions.

In Scytec’s following commentary to evolve shop floors around the world, we will explore the crucial role that Industry 4.0 technology plays in augmenting digital twin software, with a focus on the exemplary CGTech VERICUT and its integration with Scytec DataXchange in the VERICUT module titled CNC Machine Connect.

Understanding Digital Twins

What is a “Digital Twin” and why do you hear so much about them in the modern manufacturing lexicon? Digital twin technology has emerged as a game-changer for manufacturers across various sectors. Essentially, a Digital Twin is a virtual replica or simulation of a physical product, process, or system. CGTech’s flagship VERICUT enables end users to perform realistic 3D simulations of entire CNC machines, just like they behave out on the shop floor during the actual cutting process.

Integrating Industry 4.0 with Digital Twins

Industry 4.0 and its corresponding technology/software, often referred to as the fourth industrial revolution, leverages advanced technologies to create interconnected, intelligent manufacturing ecosystems. Scytec DataXchange machine monitoring has been at the forefront of IIoT technology since 2012, providing manufacturers insight and visibility into what goes on inside their shop floors and providing manufacturers with new workplace processes and cultures.

CGTech VERICUT is a leading Digital Twin software solution that enables manufacturers to simulate, optimize, and validate their manufacturing processes. By incorporating Industry 4.0 technology, VERICUT can offer a host of additional features and capabilities that drive efficiency and productivity. Let’s delve into some key areas where Industry 4.0 technologies like Scytec DataXchange enhance CGTech VERICUT. The first being real-time data integration enabling seamless integration of data from various sources, such as IoT devices and sensors. By integrating real-time data with VERICUT, manufacturers gain a comprehensive view of their production processes. This empowers them to identify bottlenecks and make data-driven decisions for enhanced productivity.

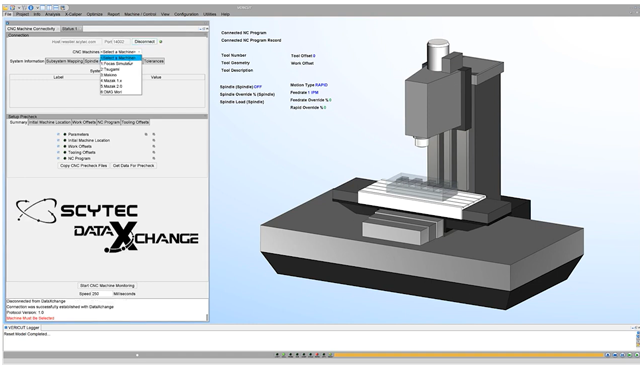

In June 2022, Scytec made an announcement for the official integration with CGTech VERICUT in the release of VERICUT 9.3 with the inclusion of a brand-new module inside of VERICUT called CNC Machine Connect. This new VERICUT module gives users the ability to connect VERICUT directly to CNC machines through Scytec DataXchange to utilize real-time data from their shop floor equipment. Through CNC Machine Connect, VERICUT users can verify machine parameters and setup details such as the main NC program, subprograms, tool offsets, and work offsets match what was simulated by VERICUT. In this case, the “Digital Twin” uses real-time data from a CNC machine enabling a remote, live representation of what the CNC machine is actually doing.

Digital Thread Integration

The next tenet of discussion will be digital thread integration with Industry 4.0 technologies. The digital thread concept, central to Industry 4.0, facilitates the seamless flow of information across the product lifecycle. By integrating VERICUT into the digital thread of Scytec DataXchange, manufacturers can ensure consistent exchange of data between part simulation, and production. This integration enhances collaboration, minimizes errors, and streamlines the overall manufacturing process by consistently adding new features that can utilize more equipment in more efficient ways.

The release of VERICUT 9.4 sees improvements for the CNC Machine Connect integration with newly supported machine protocols such as Okuma Thinc to supplement the already robust Fanuc FOCAS series supported by CNC Machine Connect. A supplementary application for the Pre-Check feature in CNC Machine Connect allows machinists to ensure that key aspects of the machine setup match what was verified in VERICUT, without checking out a full VERICUT license. Differences identified can then be investigated and resolved before running the machine and risking problems resulting from those differences.

In Conclusion

This integration of Scytec DataXchange machine monitoring with digital twin software standout CGTech VERICUT presents manufacturers with an array of benefits, allowing them to leverage data-driven decision-making, predictive maintenance, and optimization of production processes. As Industry 4.0 continues to reshape the manufacturing landscape, Digital Twin software like CGTech VERICUT and Scytec DataXchange stand as vital tools for modern-day manufacturers.