MACHINE MONITORING DASHBOARD OVERVIEW

Collecting shop floor data is one thing, making it useful is another. There is clearly value to having historical data, but having the data in a meaningful format as the activities are happening greatly increases the value of any machine data collection system. Scytec DataXchange provides a user configurable real-time manufacturing dashboard providing feedback as the data is collected in a user configurable interface. Scytec understands that lean manufacturers need up to the minute shop floor data, and equipped DataXchange with customizable manufacturing dashboards to provide feedback in real-time as utilization, downtime, and OEE data is collected.

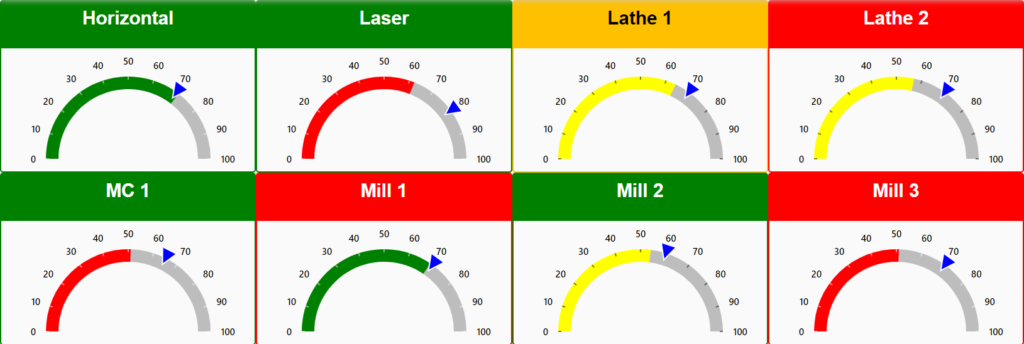

DATA DISPLAYED HOW YOU WANT TO SEE IT

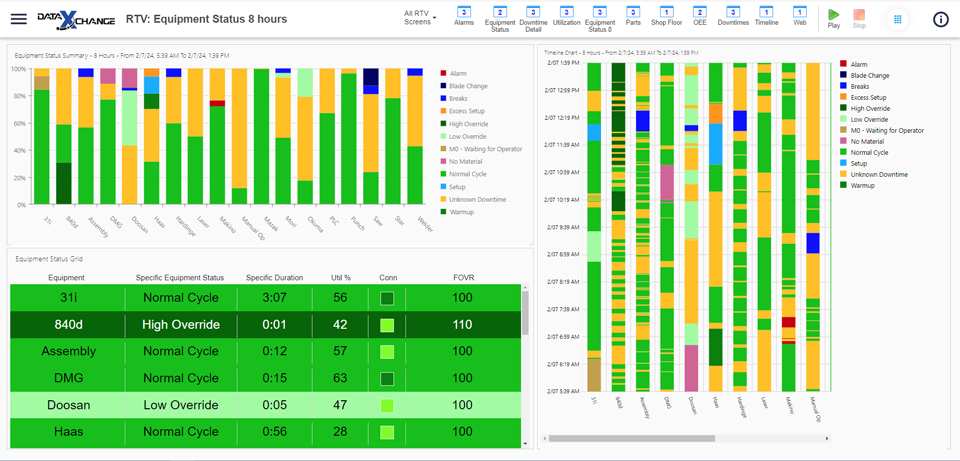

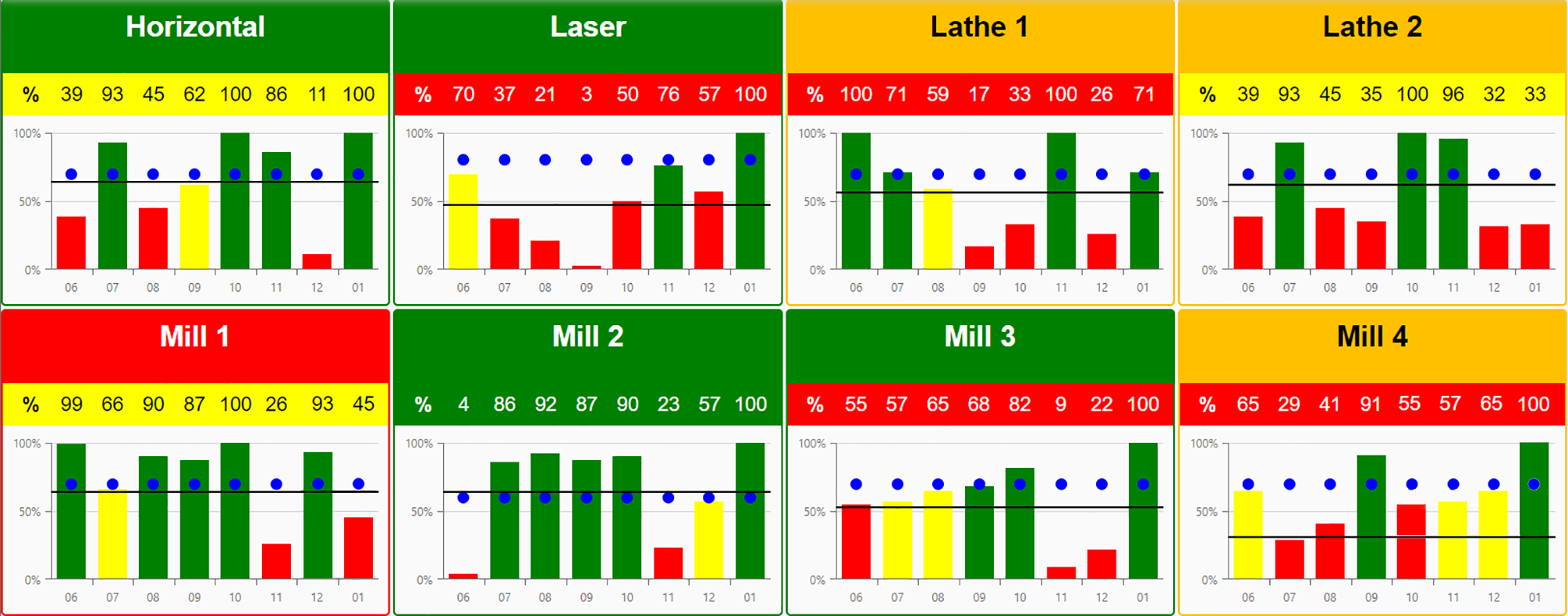

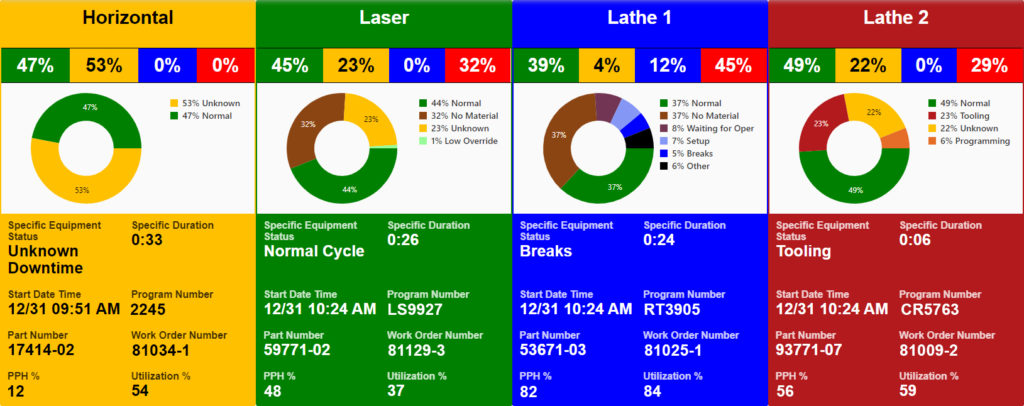

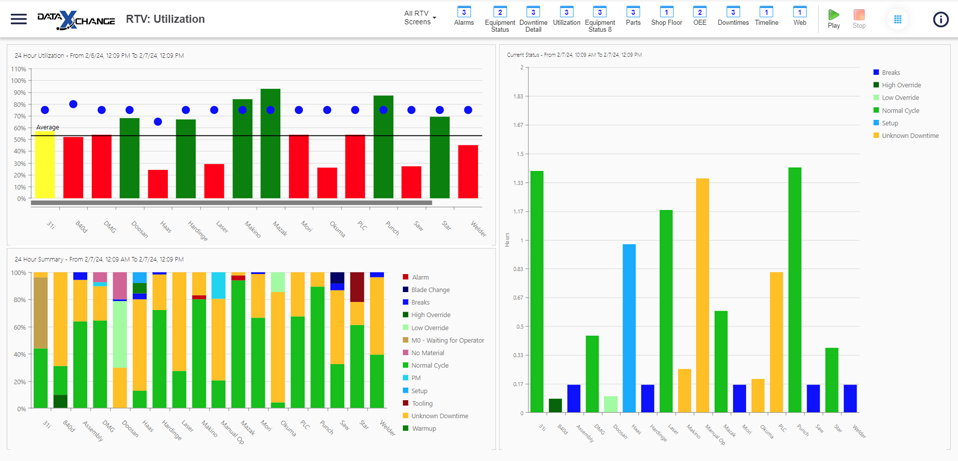

An unlimited amount of screens can be defined, with each screen showing the appropriate data for the area where the dashboard is being displayed. Show one chart, or multiple, such as the screenshot above. The Views on the screen can show the current status of the equipment, part counts, target utilization, OEE metrics, downtime Pareto’s, downtime summaries, timeline views, shop floor layouts, Caron TMAC status, and much more. In addition, each of the Views can be configured to show the data a variety of different ways, providing the metrics how you want to see them.

VISUAL MANUFACTURING

Visual information helps articulate potential issues more clearly, and the Scytec DataXchange Real Time Viewer delivers visual data to stakeholders throughout the organization through user interfaces uniquely configured to suit the needs of specific users or function areas. Visually, manufacturing data becomes accessible to more people, enabling faster decisions along with the ability to accelerate their respective workflows, leading to faster and better communication of information.

PERSONAL AND GROUP DASHBOARDS

The visual dashboards can be configured by each user for their intended use, such as machining cells. Personal dashboards allow users to customize part of the interface to suit their individual needs. Multiple personal dashboards can be created, providing quick access to a variety of different information.

For example, you can configure a dashboard for machine operators that displays machine data summarizing the amount of time in a normal cycle status, in a downtime and low feedrate override; then configure a different view displaying an OEE dashboard for shop floor managers that displays data on an entire functional area such as a manufacturing cell.

REMOTE VIEWING

With DataXchange you don’t have to be on the shop floor to view manufacturing data. The manufacturing dashboards are available on iOS and Android mobile devices, allowing you to remotely view machine data in real time from home or on the road.

UNLIMITED SCREENS WITH ROTATION

The Scytec DataXchange Real Time Viewer has customizable rotation functionality, allowing the configuration of rotating through multiple screens automatically. The rotation functionality of the manufacturing dashboard allows one TV to view an unlimited amount of information, such as having one screen display overall summaries while another screen shows the detail of specific machining centers. The rotation can also include Excel documents, show floor layout views, OEE, as well as maintenance related information.

BROWSER VIEW

The Real Time Viewer has a built-in Web Browser View. This feature allows for an internal or external web page to be displayed within the DataXchange dashboards. The Browser View can provide value by displaying company messages, data from an internal company website, ERP information, or to view an MS Office documents through Office Online.

AUTOMATIC LOGIN

TV monitors can be setup on the shop floor by each machining cell, with the Real Time Viewer configured to show the appropriate equipment for each cell. The PCs are configured to log in automatically and then Scytec DataXchange will automatically launch, login, open the Real Time Viewer, and launch the appropriate screen for display in the cell.