MACHINE MONITORING FOR THE 21ST CENTURY

Scytec DataXchange is a Cloud and On-Premise OEE and analytic manufacturing machine monitoring system, and so much more. Scytec utilized 15 years of experience creating data collection, monitoring, and OEE software solutions to develop a machine monitoring system that truly meets the needs of 21st Century manufacturing. DataXchange increases overall equipment effectiveness, utilization, and shop floor productivity through the use of innovative IIoT technology. DataXchange is compatible with a wide variety of manufacturing machines including CNCs, PLCs, robots, welders, and manual machines. Custom shop floor data entry rules can be created to automatically collect shop floor data from a wired or wireless connection on MTConnect, Fanuc FOCAS, and OPC UA-based machines as well as older and manual machines. As the machine data is collected, DataXchange has all the OEE reports, charts, dashboards, and notifications you need to analyze the information in a meaningful way as well as triggering notifications. The features and benefits of DataXchange make it a machine monitoring software that meets the manufacturing data collection needs of small facilities as well as large multi-site enterprise level operations.

IMMEDIATE VALUE

Consider what your shop rate is along with the cost of lost productivity time. Now, by everyone knowing exactly what the machines are doing at all times, and by receiving proactive notifications, could you increase machine uptime by 30 minutes a month per machine? (easily!) Increasing machine utilization by roughly 30 minutes per machine will cover the cost of the software. How about the gains of knowing when machines are running at a lower feedrate override, or sitting in a program stop or feed hold? It’s easy to see how the software typically pays for itself within the first few days of each month.

SIMPLIFIED LICENSING & PRICING

When developing DataXchange, Scytec addressed everything from start-up costs and licensing obstacles to software updates and ongoing support. Licensing is determined by the amount of machines utilizing the software, and pricing discounts are offered as the quantity of connected equipment increases. All license levels of DataXchange include unlimited reporting, charting & dashboards. The low start-up costs and straightforward licensing options make DataXchange a scalable and cost-effective OEE and machine monitoring system for all types and sizes of manufacturers.

CLOUD MANUFACTURING

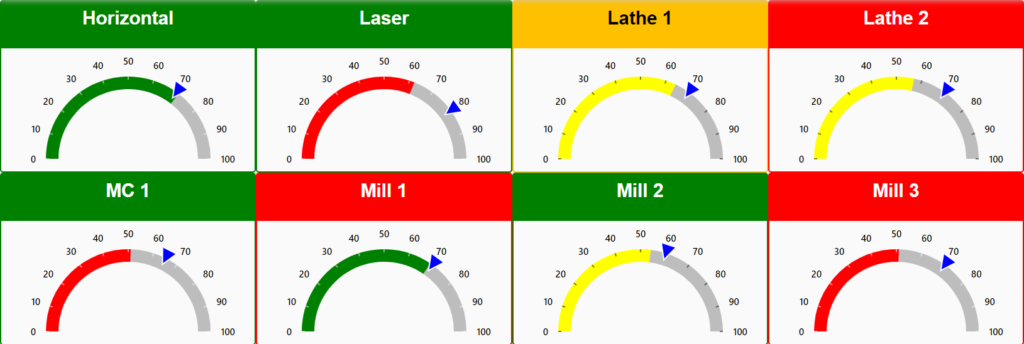

The cloud based implementation of DataXchange OEE software allows managers to view machine usage stats in real-time on a mobile device with the manufacturing dashboard. Proactive alerts can be sent via text or email to notify managers and machine operators if a machine is down or in a low override mode, and machine operators can use PCs or tablets to enter shop floor data such as machine downtime codes and part numbers. The flexibility of cloud based machine monitoring leads to reduced machine downtime and increased shop floor productivity, making DataXchange a machine monitoring system that meets the needs of small manufacturing shops producing one off products as well as large multi-site operations producing thousands of products.

SCHEDULE A FREE DEMO

To learn more about how DataXchange can increase productivity and profitability at your manufacturing facility, contact our sales team to schedule a free demo.