ONWARD and UPWARD: SCYTEC DATAXCHANGE’S END OF YEAR REVIEW AND WHATS NEXT

Welcome to the forefront of continuous improvement in the modern manufacturing realm! In our continual commentary, Scytec embarks on a journey through the latest DataXchange machine monitoring updates in the 2023 year where shop floor efficiency meets data-driven excellence. In a world where precision and speed define success, staying ahead of the curve is not just an advantage but a necessity. This blog unveils the most recent strides in Scytec’s machine monitoring platform and explores how these updates are reshaping not only DataXchange but the manufacturing industry at large by empowering shop floors to streamline processes, boost productivity, and achieve unparalleled success.

Saved and Scheduled Charts

The Scytec DataXchange machine monitoring platform was developed from its inception to fit into your already stretched thin manufacturing day-to-day duties with ease. Scytec raised the bar again earlier this year with the addition of Saved and Scheduled Charts inside the Scytec DataXchange machine monitoring platform for streamlining your smart manufacturing experience and ensuring the arrival of need-to-know shop floor metrics straight to your inbox.

Saved Charts allows DataXchange users to access their favorite and most needed manufacturing charts from the landing page of the browser-based Data Display application. This is a beneficial addition to the already robust machine monitoring platform for allowing all production floor employment levels to be able to access the needed metrics of their production environment and specific machinery regardless of where they are physically present at the time of request.

Scheduled Charts are a boon for management-level operations to have the necessary charts sent to themselves and other relevant employees on a recurring schedule so they can focus on the daily production goals and have the reassurance that machinery is performing optimally. For example, Scheduled Charts inside DataXchange can be customized to be sent to your inbox before having a Gemba walk about the previous day’s production metrics or a timeline chart showing the trending production metrics for the last week, month, or quarter so that you are adequately prepared and aware of the previous machine status trends.

Streamlining The RTV

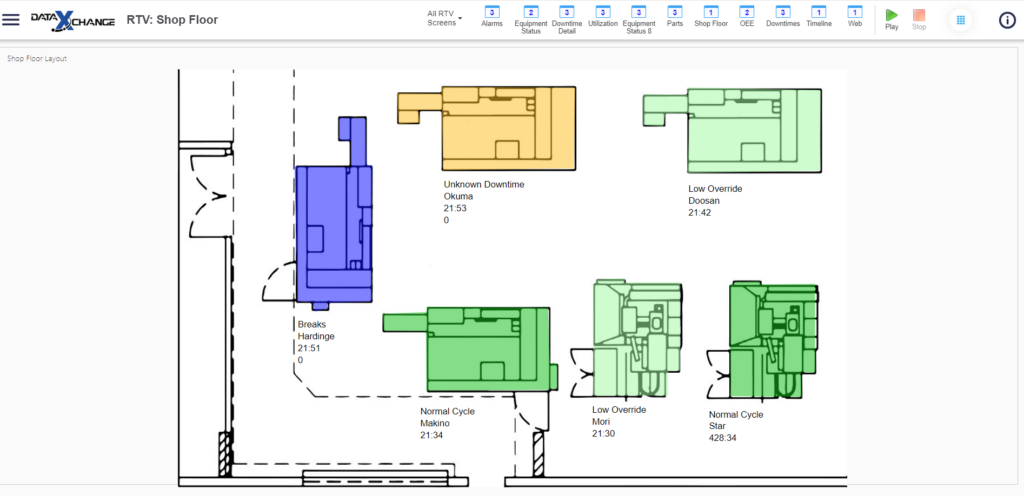

The Real-Time Viewer (RTV) inside of Scytec DataXchange has revolutionized shop floors by allowing shop floor personnel to see rotating manufacturing dashboards with customized views of their production environment. Historically the RTV found its users gaze upon a television that would be out on the shop floor or in the break room where manufacturing professionals could see an overhead view of their shop floor’s machines and statuses. Customers now have the option of viewing the RTV through either the client application or through a browser, providing even more options for deployment on shop floors, management offices, and corporate meeting rooms.

CNC Machine Connect: The Standout Manufacturing Integration Keeps Improving

Originally announced in 2022 for the release of VERICUT 9.3, a strategic partnership between CGTech and Scytec came to fruition with a new module inside of VERICUT called CNC Machine Connect. The first offering for this module included the initial offering Pre-Check. This integration allows users to seamlessly link VERICUT with CNC machines via DataXchange, enabling the utilization of real-time data from the shop floor elevating their CNC digital twin simulations to new heights by generating the most precise manufacturing simulation and fostering a more efficient manufacturing process without any machine crashes.

This past June, the release of VERICUT 9.4 saw the release of more features to the heralded Scytec and CGTech partnership. A standalone application for Pre-Check was released that allowed machinists to ensure that key aspects of the machine setup match what was verified in CGTech VERICUT, without checking out a VERICUT license.

The biggest announcement from the release of VERICUT 9.4 came with the arrival of CNC Machine Monitoring, a live-streaming feature for VERICUT. CGTech CNC Machine Monitoring allows you to live stream and monitor what your machines on the shop floor are doing in real-time, within CGTech VERICUT. When you are not able to observe your CNC machine by standing next to it, find answers to questions like: is my machine running? What cutting tool is currently loaded and what active work offset is being loaded? Is the machine running at 100% or has an override been adjusted?

More will be released for this incredible integration and partnership in the year 2024 including Post Check. Stay tuned for more information.

Additional Machine Insight to Enhance Visibility into Your Shop Floor

So, what is to come for Scytec DataXchange in the near future and how will the start of 2024 see continuous improvement?

Enabling a deeper understanding of ongoing activities is a prime example for manufacturing use with the DataXchange machine monitoring platform. Scytec will be providing even further insight into your CNC machines by offering a level of detail not offered by other machine monitoring platforms. In the next year, Scytec DataXchange users will be able to get the most specific Data Items from machinery that includes Heidenhain and Mazak. DataXchange users will get to see more information pulled off machines that can detail things far beyond “is my machine running or not running?” Earlier this year the Okuma was one of the major machine brands to be able to witness the most detailed information available on the market by offering trackable metrics not offered by more rudimentary options.

Scytec, and DataXchange its machine monitoring application are committed to providing manufacturers across the globe with the most innovative smart factory solutions available. Stay tuned as we are just getting started.