Embracing Cloud Storage for Smart Factories

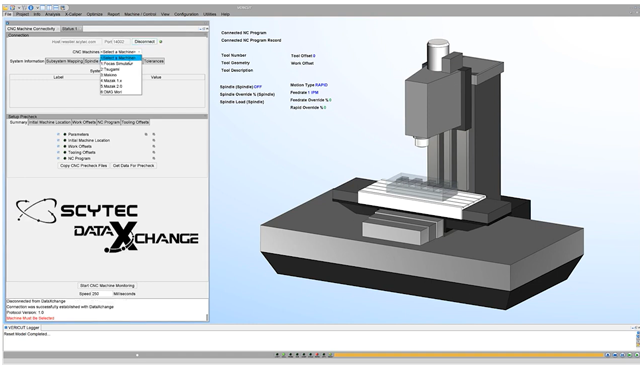

In the ever-evolving landscape of modern manufacturing, IIoT technology continues to shape the way we operate modern factories. One of the significant advancements that has continued to gain traction is the utilization of cloud storage for smart factory systems. Scytec DataXchange is the only machine monitoring solution that offers an…