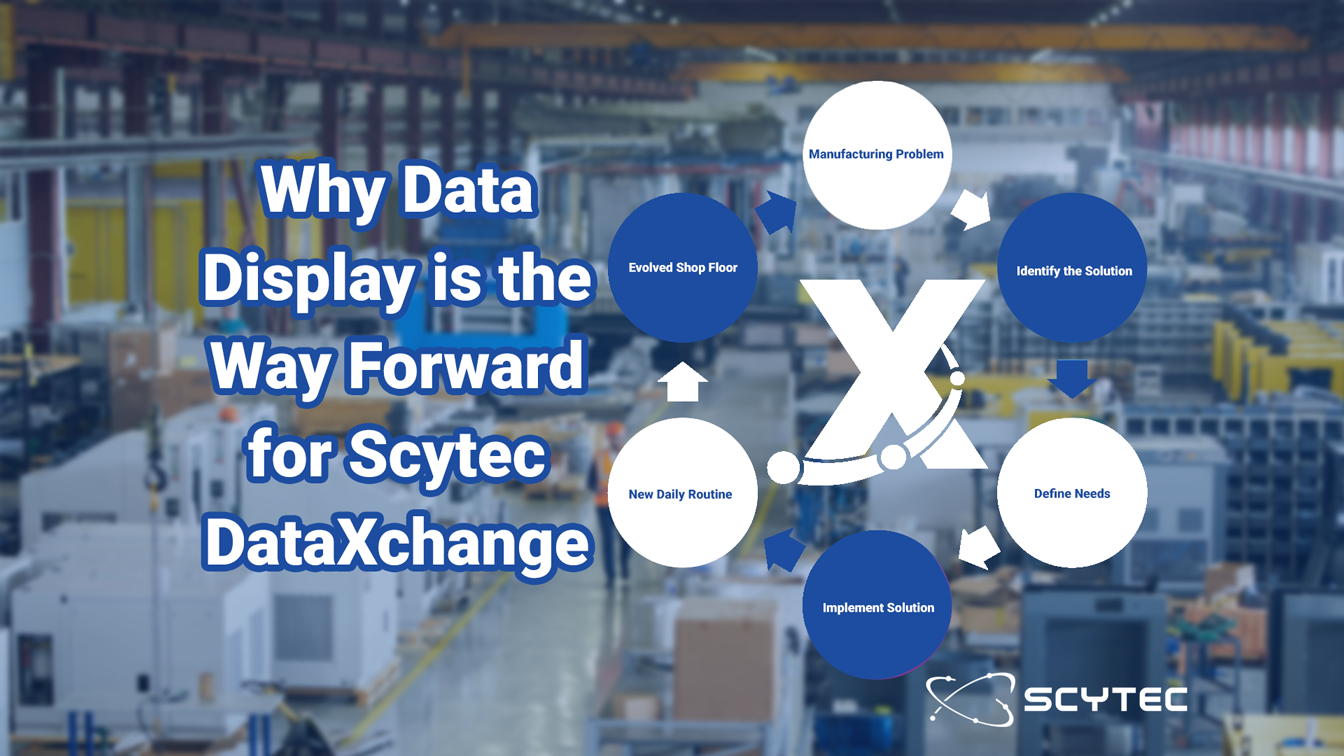

Why Data Display is the Way Forward for Scytec DataXchange and How it Directly Relates to Kaizen Principles

In the dynamic landscape of manufacturing, staying ahead of competitors requires more than just keeping up with the latest technology, it demands a commitment to continuous improvement.

Kaizen, a term from Japanese philosophy whose meaning can be interpreted as “continuous improvement”, serves as a guiding principle for manufacturers striving for excellence in their processes, products, and overall performance. Acceptance of Kaizen principles is not only about making necessary changes and being proactive; it is about fostering a production environment’s culture of ceaseless evolution and refinement. In the IIoT age, one of the most powerful tools for driving Kaizen forward is the Scytec DataXchange machine monitoring platform and its browser-based reporting application Data Display.

Scytec DataXchange made its official unveiling to the world of manufacturing in 2012 to revolutionize the way that outdated manufacturing was able to produce shop floor metrics. Traditionally, monitoring and optimizing manufacturing processes involved manual data collection, lengthy analysis periods, and often reactive decision-making that was done after the fact. The DataXchange machine monitoring platform offers real-time insights into CNC and shop floor equipment performance, production efficiency, and downtime analysis – all of which is accessible from any common technological devices. The concept of Kaizen has been kept in mind since the inception of Scytec DataXchange and itself has seen many updates that have been requested by end users to ensure everyone keeps continually improving.

Scytec DataXchange was elevated with the subsequent release of its browser-based iteration Data Display, broadening the scope of viewable devices so that all levels of employment in a production facility were privy to the benefits of smart factory technology. With further feature update releases, DataXchange users now find features that were previously only found in the desktop client of DataXchange now being included in Data Display such as the Real Time Viewer (RTV) charts and welcomed Data Display-focused additions such as saved and scheduled charts.

This might leave you wondering, is Data Display going to be the main source of DataXchange machine monitoring for most end users? Simply put, yes, and in the commentary below we will delve into why doing so is directly related to Kaizen principles.

Commonality Enables Real-time Visibility and Immediate Action

Kaizen principles emphasize the importance of making small, incremental changes to improve processes over time. Utilizing the real-time visibility provided by Data Display’s browser-based machine monitoring software, manufacturers can identify issues the moment they occur via their Android or iOS smartphone with real time viewing options like the Equipment View or Real Time List. The ability to have this viewing option from something that is almost guaranteed to be in the pocket of all your shop floor personnel makes Data Display and its future evolution from the development team at Scytec a must-have for any facility that demands lean production.

Whether it’s a machine or cobot experiencing unexpected downtime, a prolonged setup or pause that leads to a drop in production efficiency, or any deviation in terms of availability, performance, and quality an immediate reaction can be realized by an employee with Data Display on their smartphone. After continual use of Data Display, bottleneck trends will emerge that will allow you to continually improve.

Cross-Device Accessibility Fosters Collaboration and Engagement

Effective Kaizen implementation requires active participation and collaboration across all levels of an organization. Browser-based monitoring platforms such as Data Display, which are accessible across multiple devices, facilitate seamless collaboration among operators, supervisors, engineers, and managers. Whether it’s viewing the shop floor performance metrics in a break room or out on the cutting floor via the rotating RTV dashboard, or coordinating action plans in a production meeting, the accessibility of Data Display promotes a new culture of engagement and teamwork essential for sustained Kaizen success that can easily fit into a daily routine.

Where Does This Leave the Desktop Client?

If you have been a long-time user of Scytec DataXchange, fear not the desktop version you have been using is not going anywhere. The desktop version is now serving a more focused purpose. The value of Data Display can be found in the idea that it is meant to be the most streamlined machine monitoring platform on the market and in doing so Scytec wanted all the most pertinent manufacturing charts and dashboards to be available quickly and efficiently for many of the end-users in your shop floor. Going forward, the desktop version is going to be focused on the configuration side of your machine monitoring experience with a user base more geared towards managers, IT departments, and those doing the implementation. Inside the desktop version, you will still be able to configure your notifications and define user groups and their security permissions and a plethora of other setup items. Scytec wants your machine monitoring experience to be one founded on principles of continuous improvement and was certain that Data Display is the way to move forward for machine monitoring end users.

In conclusion, as manufacturers strive to optimize efficiency, quality, and competitiveness, integrating browser-based machine monitoring platforms into their Kaizen initiatives isn’t just a smart move – it’s a strategic imperative that many are still waiting to implement. By leveraging smart factory technology to drive continuous improvement, manufacturers can navigate the ever-evolving landscape of modern manufacturing with confidence, agility, and resilience.